Rivets – not nuts

Leave a comment10. July 2024 by Peter

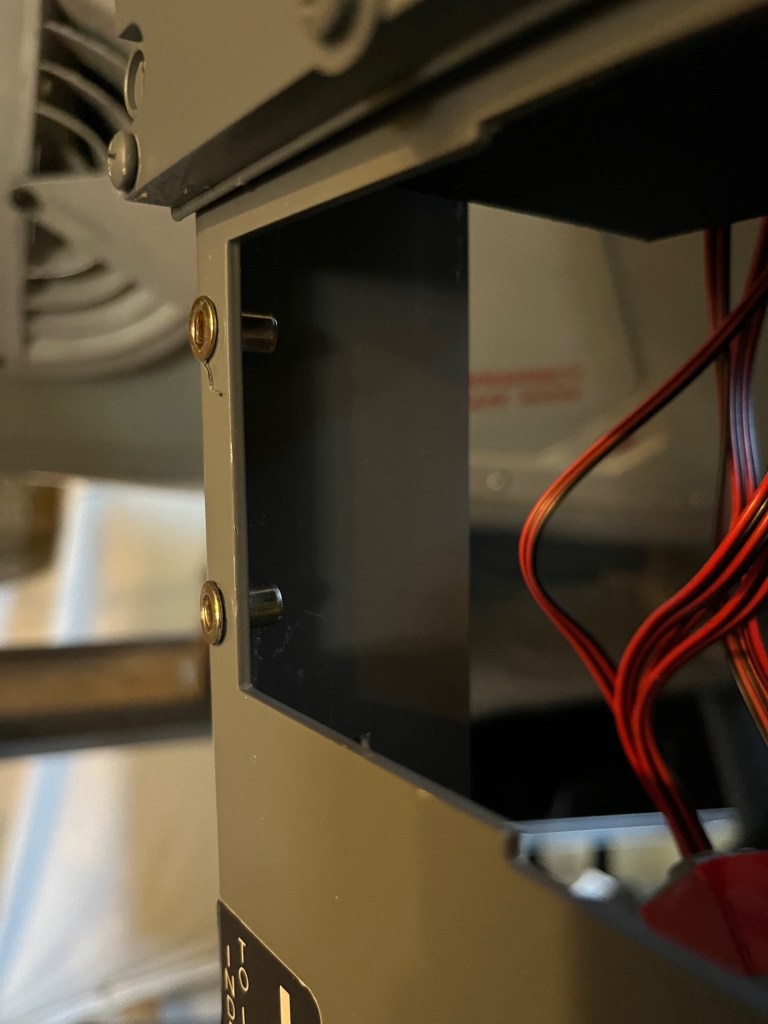

This is a shout out to Jimmy from Götenburg / Sweden. A fellow cockpit builder that visited me a few years ago and gave me an advice that I would like to pass on: Use rivets for mounting panels.

In a real cockpit, panels are fastened onto a dzus-rail. A rail with holes and a wire/rod running behind the holes. The corresponding dzus-srews are a special design that grabs onto the rod and when turned a quarter locks itself in place.

Dzus-rails are hard to find. And Dzus-screws are a complex mechanism, so no 3d-printing. So you want to do everything OEM if you plan on using Dzus. That is why most cockpit-builder just use regular screws and nuts when fastening panels.

The screw+nut solution is a low-tech easy to use solution. However, it holds one big disadvantage: The nut on the back needs to be hold in place when fastening. You can try with hot-glue. But really – rivets are the answer to your problems.

The rivets come with a thread inside making it easy to insert the screw and fasten the panel.

Only downside is the need to drill bigger holes in your overhead to fit the rivet. I use M4 screws so each rivet needs a 6mm hold to fit. Easy done. The rivet tool itself I got from the local DIY store and stood me in €30. Very easy to use. You just put on the rivet and squeeze the handles together until it goes pop.

Thanks Jimmy for the advice