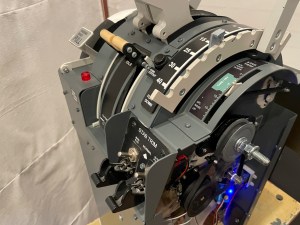

FSC Throttle Kaputt?!?

Leave a comment30. November 2023 by Peter

I thought it was just a matter of plug and play with my new throttle and then fly away. Well it did not work. Luckily it now works. But at one point I thought it was all kaputt…

Levers not working

The throttle is natively supported by Prosim737. This means it’s just a matter of plug and play and then you’re ready for takeoff. However when I plugged in the throttle only the switches was working. No levers were working was working at all. I was a bit puzzled by this, because if switches were working, the throttle was not toast. So I tried to replace one of the potentiometer and all of a sudden that lever was working! So I concluded I had to change all the potentiometers. I did so then all of a sudden: voila! The handles were alle working!

The throttle used 5 x B100K potentiometers. Linear. Standard pots.

Trim gauge

The two trim gauges are not interfaced. Therefore, I designed a bracket for a 9g servo that could move the indicator back and forth assigning. The bracket took some time to design/Prototype. But apart from that it was pretty straightforward. The two servos are interfaced on a Pololu maestro card. I really like those carts. They are stable.

In case someone are modifying their FSC throttle write me an email and I will supply the files for 3-D printing the brackets.

Trim wheels

The trim wheels are able to turn, but they’re not interfaced. In order to interface them I used a pulley belt and an encoder. So when I turn the trim wheels it’s registered by the encoder and I am able to trim the aircraft that way. However no motorization at this time.

Furthermore I painted it black with a white stripe on. That didn’t turn out that well. My skills in spray-painting apparently isn’t as good as I hoped. 🙂

Other modifications

I provided backlightning for the two decals. It’s just an 12 V LED strip so no big issue there. Furthermore, a few switches was interfaced.

One thing that I really spent some time on was the two flaps guards at position, 1° and 15°. The throttle is prepared for mounting a rail in those positions. But I had to design it and 3-D printed myself. That took forever. I spent around a week prototyping. Each prototype took a long time, so it was really a slow process, getting the angles and distances all correct.

I also put grease onto different plastic parts. They were squeaky, but after putting some grease onto them they’re all smooth and silent.

Finally, I 3-D printed a cylinder for the handles on the trim wheels. They were mounted using a square bracket which made it unable to pull out the handle replacing that square with a cylinder of the same dimension. I’m not able to pull the handle is out if I want to.

Overall evaluation

First, let me say that the FC throttle really is a fantastic unit. It is all metal built and it’s very sturdy. No question that the mechanics inside is also very good. It’s well designed.

One thing that puzzles me, though, is a few things that wasn’t interfaced or done as supposed to. A few switches that could easily be wired up, and the trim wheel just required a cylinder instead of a square to work. Small things like that, just made me think, if FSC somehow would be downgrading, this version compare to the motorised version.

It took a few weeks to modify this, but I’m very happy with the FSC throttle. It is a great unit and if you are able to get your hands on a used version, you should definitely spend the bucks